Biocarbon engineered concentrates that improve plastic products

Effortless processing with powerful performance

Engineered to excel,

effortless to use.

Benefits of using the Carboganic masterbatch in thermoplastics

Biocarbon

Weight reduction

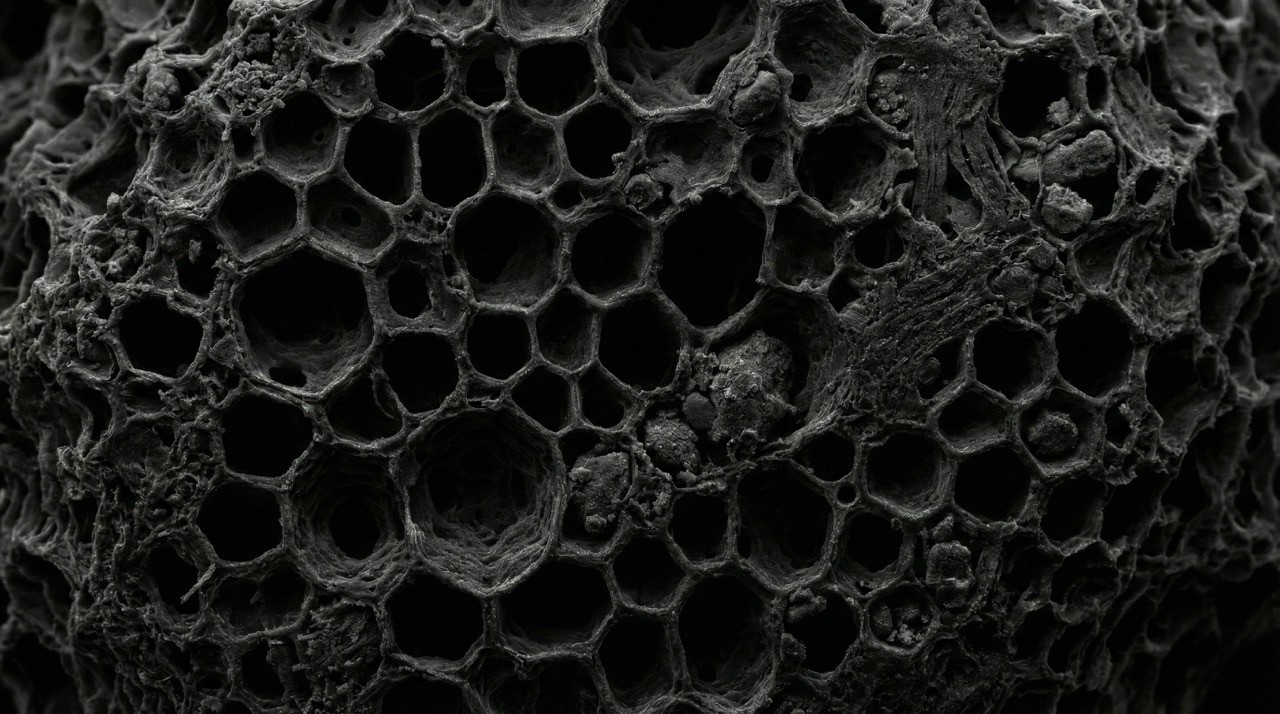

Fibre reinforcing

Improved thermostability

Fire retardant

Augmont's dimensional stability

Stiffness enhancement

UV stability

Odour scavenging

Black biobased pigment

CO₂ footprint reduction

Masterbatch

Superior processing resulting in better properties

Drop in material

Easy to handle

One pack solution with multiple functionalities

Improved compounding of immiscible materials

Facilitating compounding of recycled plastics

For the end customer

Outperforming material features

Unique functionalities

Renewable locally sourced resource

Fossil carbon footprint reduction

Value priced benefits

ABOUT US

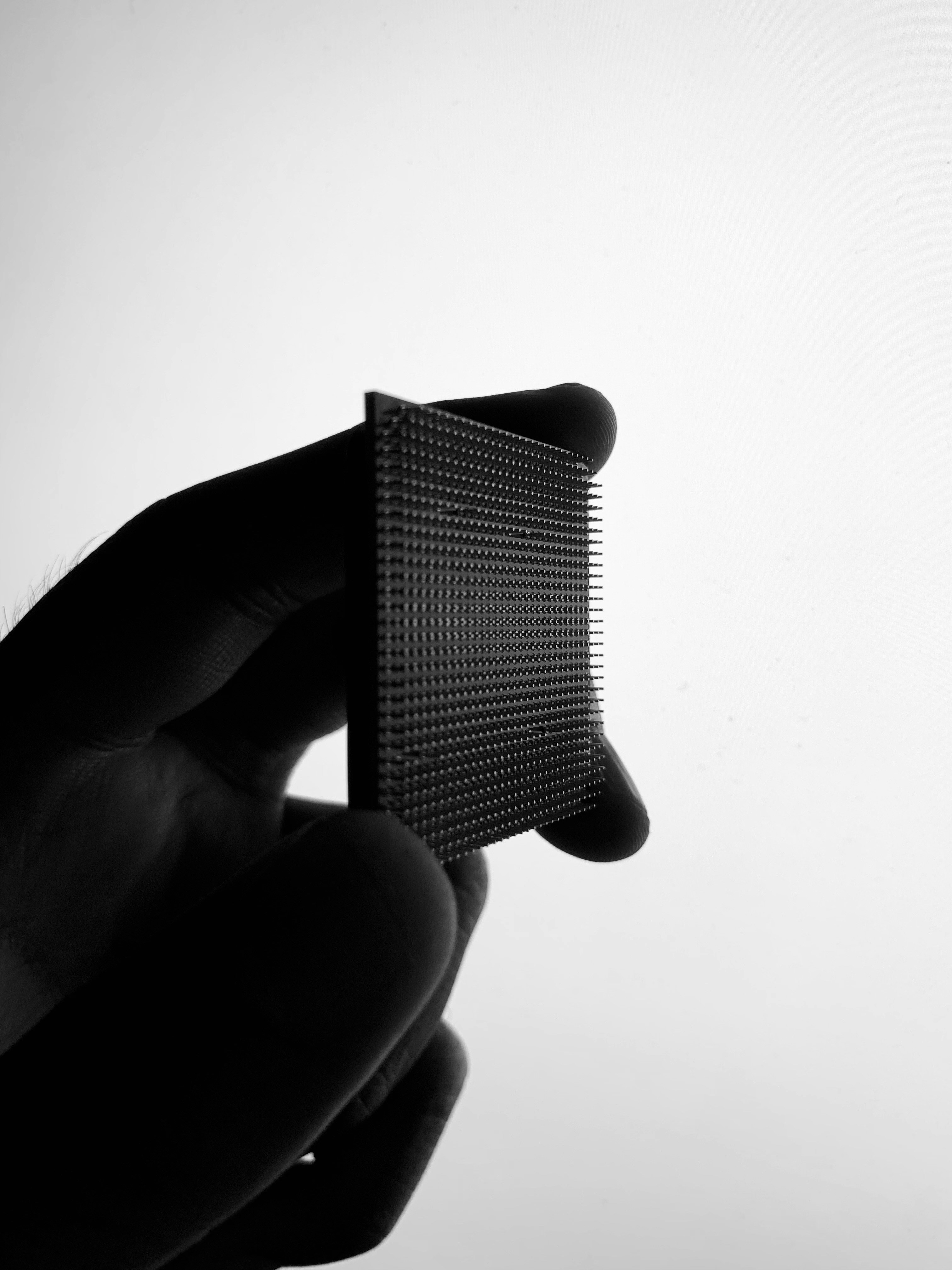

Masterbatch production plant

Carboganic manufactures in-house functional biocarbon masterbatches, engineered for reliable performance and seamless integration into polymer applications.

Compounding line

Our integrated compounding line enables efficient development and customization tailored to client-specific performance needs.

Co-design development

Get in touch

Fill in your information via our get in touch button.

Tell us your needs

We listen to understand your goals and challenges.

Technology fit

Once we know your requirements our specialists evaluate your case and if our materials and technology match with your idea.

Co-formulation

Together we develop, test, and refine possibilities and prototypes.

Final product

We deliver your ready to use solution.