Engineered to excel,

effortless to use.

Benefits of using the Carboganic masterbatch in thermoplastics

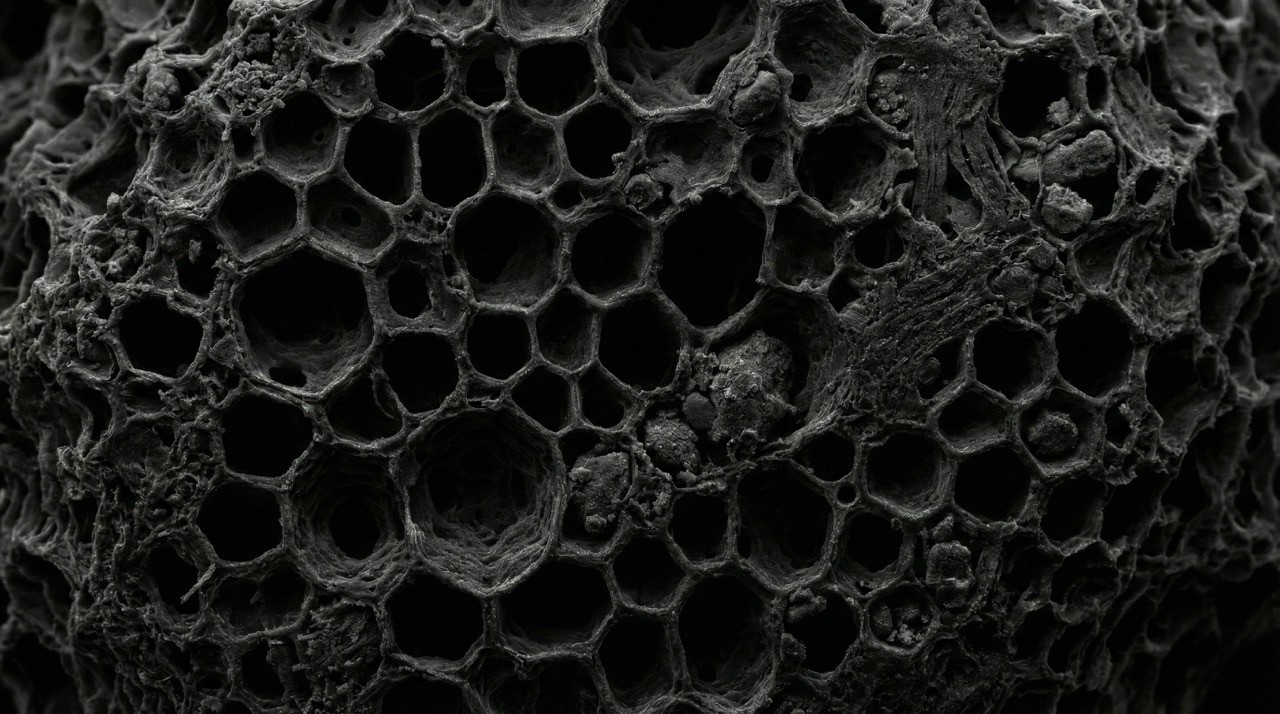

Biocarbon

Weight reduction

Fibre reinforcing

Improved thermostability

Fire retardant

Augmont's dimensional stability

Stiffness enhancement

UV stability

Odour scavenging

Black biobased pigment

CO₂ footprint reduction

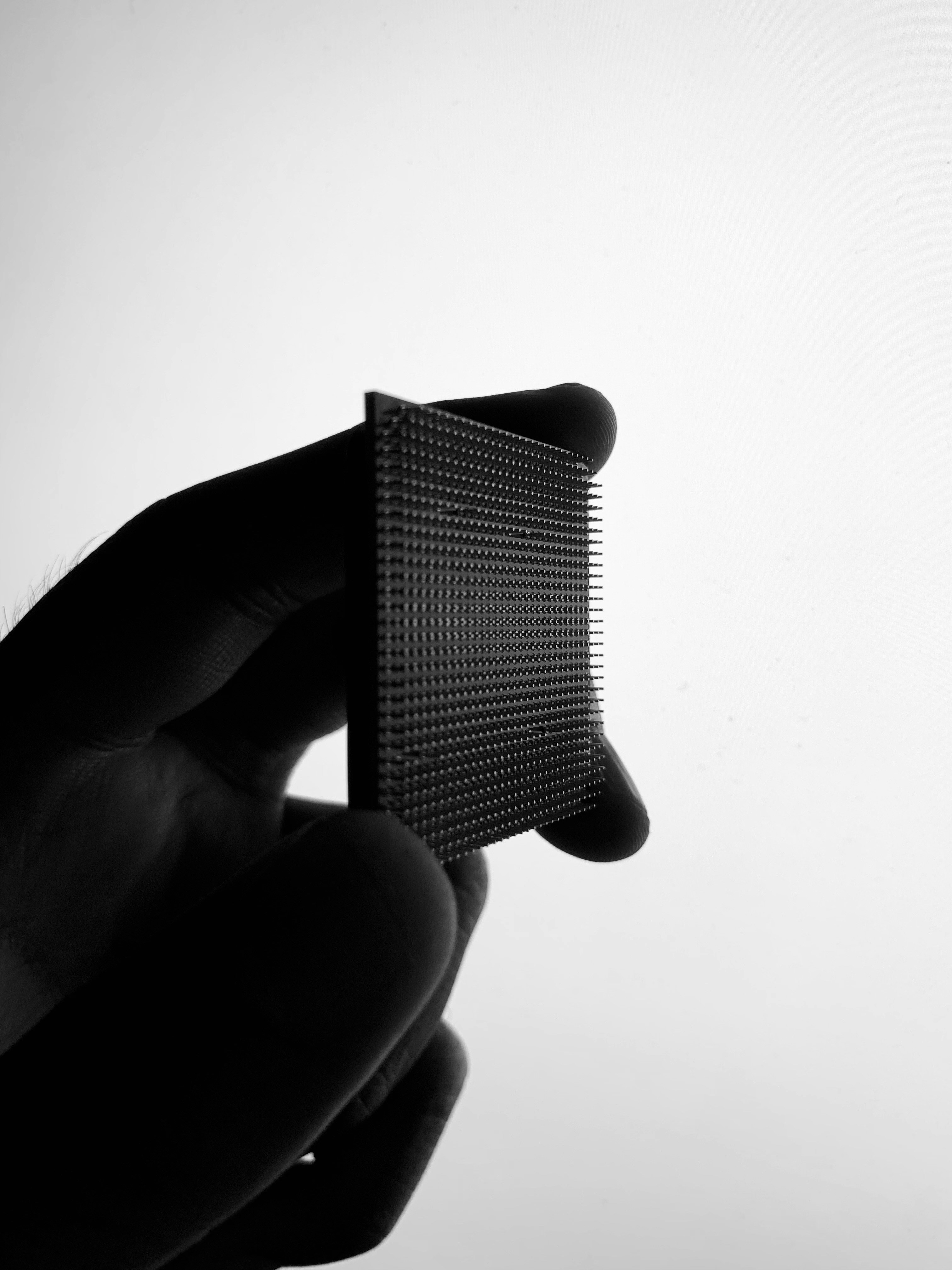

Masterbatch

Superior processing resulting in better properties

Drop in material

Easy to handle

One pack solution with multiple functionalities

Improved compounding of immiscible materials

Facilitating compounding of recycled plastics

For the end customer

Outperforming material features

Unique functionalities

Renewable locally sourced resource

Fossil carbon footprint reduction

Value priced benefits

High performance biocarbon concentrates

True advancement in material science is found where sustainability meets unyielding performance. While traditional natural fibers often compromise the integrity of a plastic matrix, engineered biocarbon act as a powerful improving agent, rewriting the potential of polymers.

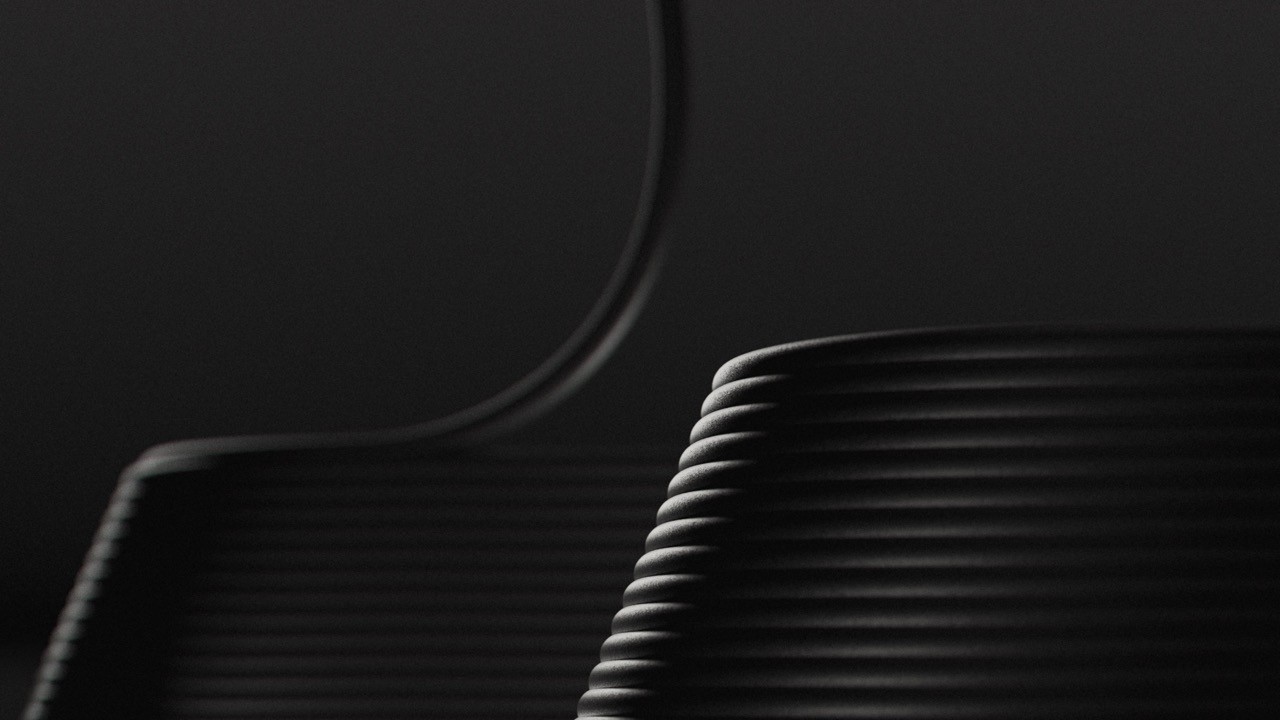

Co-design development

We apply a co-design development approach across the full biocarbon compounding value chain, supporting material development through compounding, application optimization, and end-product integration for engineered polymer applications.

Masterbatch production plant

Carboganic manufactures in-house functional biocarbon masterbatches, engineered for reliable performance and seamless integration into polymer applications.

Compounding line

Our integrated compounding line enables efficient development and customization tailored to client-specific performance needs.

Enabling countless possibilities across industries

We apply a hands-on co-design approach to ensure our materials fit your specific technical requirements perfectly. Tell us about your goals below, and our specialists will evaluate the best technology fit for your project.